CNC Router Machines: The evolution of technology has brought significant advancements to various industries, including woodworking. Among the groundbreaking innovations, the CNC (Computer Numerical Control) router machine stands out as a pivotal tool for enthusiasts and professionals in the wood crafting field. This sophisticated equipment has transformed the way wood items are designed, cut, and finished, opening up endless possibilities for creativity and precision.

Introduction to CNC Router Machines for Wood

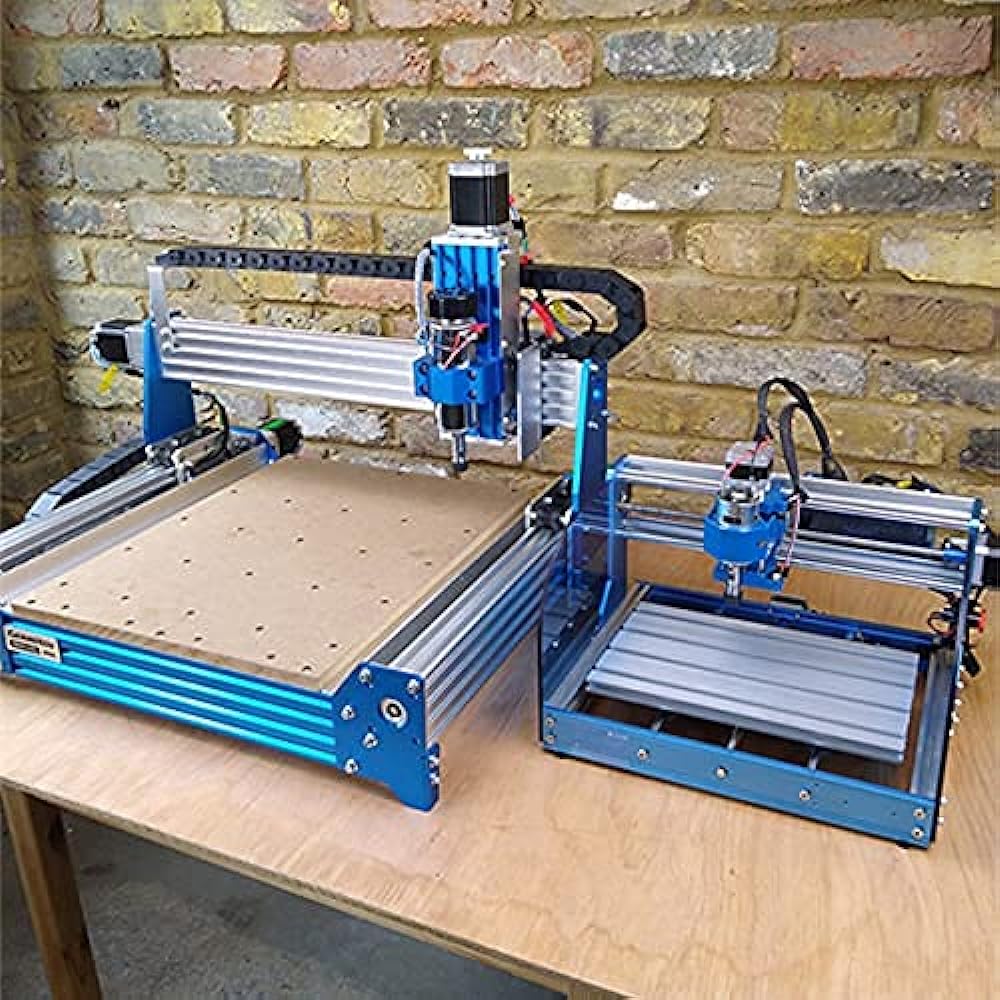

CNC router machines for wood are automated systems that meticulously carve, engrave and shape wooden materials with unparalleled accuracy. By interpreting design instructions from computer software, these machines execute complex cuts that would be extremely difficult, if not impossible, to achieve manually. The versatility of CNC routers allows for the production of intricate patterns, precise fittings, and smooth finishes on a variety of wood types.

The Mechanism Behind the Magic

At the heart of a CNC router’s functionality is its design software, often referred to as CAD (Computer-Aided Design). The software allows users to create detailed 2D or 3D models of their desired outcomes. Once the design is finalized, it is converted into a language (G-code) that the CNC router can understand, dictating every move from the depth of cut to the speed of the router’s movement.

The machine itself is equipped with a robust cutting tool that moves along three or more axes, providing the ability to create depth in carvings as well as intricate details on the surface of the wood. The precision of CNC routers ensures that each piece is consistently produced to the highest standards, eliminating the variability often associated with handcrafted items.

Applications of CNC Routers in Woodworking

CNC routers have revolutionized woodworking, enabling the production of everything from simple home decorations to complex furniture pieces with ornate designs. These machines are also instrumental in sign making, creating detailed logos and lettering from wood. In the architectural domain, CNC routers are used to produce wooden frames, panels, and moldings with consistent quality and speed.

Advantages of Using CNC Routers

One of the primary benefits of employing CNC routers in woodworking is the significant increase in efficiency and productivity. These machines can operate continuously, producing large quantities of items in a fraction of the time it would take to make them by hand. Additionally, the precision and repeatability of CNC routers reduce material waste, making them a cost-effective solution for both small-scale projects and large production runs.

Another advantage is the reduction in the physical strain on craftsmen. Traditional woodworking is labor-intensive and can lead to fatigue and injuries over time. CNC routers, however, do the heavy lifting, allowing craftsmen to focus more on the creative aspects of design and finishing.

Getting Started with CNC Routing

For those interested in integrating CNC routing into their woodworking projects, several key factors should be considered. The size of the router needed depends on the scale of the projects planned. Smaller machines are suitable for hobbyists and small businesses, while larger, industrial-grade machines cater to high-volume production environments.

Choosing the right software is also crucial, as it affects the ease of design and the complexity of projects that can be undertaken. Many CNC routers come with proprietary software, but third-party options are also available, offering different features and levels of user-friendliness.

Safety and Maintenance

While CNC routers are automated, safety should never be overlooked. Proper training on machine operation and safety precautions is essential to prevent accidents. Regular maintenance of the machine, including cleaning and checking for wear on cutting tools, ensures optimal performance and longevity.

Conclusion

The CNC router machine has established itself as an indispensable tool in the woodworking industry. Its ability to execute intricate designs with speed and precision has not only enhanced the quality of wood products but also expanded the creative potential of those who work with wood. Whether for a hobbyist looking to explore new designs or a professional aiming to increase production efficiency, the CNC router offers solutions that push the boundaries of traditional woodworking.

As the technology continues to evolve, the future of woodworking with CNC routers looks promising, with advancements aimed at increasing automation, improving user interfaces, and expanding the capabilities of these remarkable machines. The journey into the world of CNC routing is an exciting venture that combines the age-old art of woodworking with cutting-edge modern technology, paving the way for innovation and craftsmanship to flourish side by side.