Energy efficiency is a critical concern in today’s world, particularly within the oil and gas sector. As industries strive to minimize their carbon footprint and reduce operational costs, innovative solutions like pipe insulation wrap have gained prominence. At G & R Insulating, we understand the vital role that quality insulation plays in energy conservation. This blog post delves into the ways pipe insulation wrap enhances energy efficiency, providing a comprehensive overview for industry professionals and enthusiasts alike.

Understanding Pipe Insulation Wrap

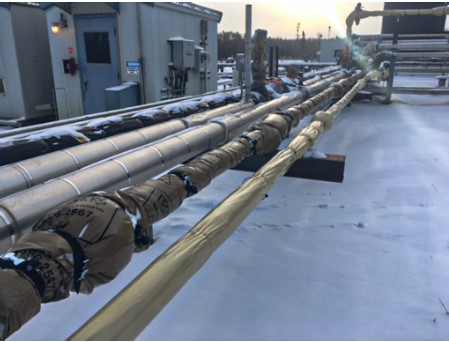

Pipe insulation wrap is a flexible material designed to insulate pipes, preventing heat loss or gain. Typically made from materials such as fiberglass, foam, or rubber, these wraps are easy to install and maintain. The primary purpose is to maintain the temperature of the fluid within the pipes, thus ensuring system efficiency and energy savings.

Reducing Heat Loss

One of the most significant benefits of pipe insulation wrap is its ability to reduce heat loss. In industrial settings, uninsulated pipes can lose a substantial amount of heat to the surrounding environment, leading to increased energy consumption. By wrapping pipes with insulation, heat is retained within the system, maintaining the desired temperature and reducing the need for additional heating.

Preventing Heat Gain

Just as pipe insulation wrap prevents heat loss, it also protects against heat gain. This is particularly important in systems that transport chilled fluids. Without insulation, external heat can penetrate the pipes, causing the fluid to warm up and the cooling system to work harder. Pipe insulation wrap acts as a barrier, keeping external heat at bay and preserving the efficiency of the cooling system.

Enhancing System Efficiency

Efficiency is paramount in any industrial system. By maintaining consistent temperatures, pipe insulation wrap helps systems operate more smoothly and effectively. This stability reduces the strain on heating and cooling systems, leading to fewer breakdowns and longer equipment lifespan. Consequently, businesses can save on maintenance and replacement costs.

Lowering Energy Consumption

Energy consumption is a significant expense for industrial operations. Pipe insulation wrap plays a crucial role in lowering these costs by reducing the amount of energy needed to heat or cool fluids within the pipes. With less energy required to maintain optimal temperatures, companies can achieve substantial savings on their energy bills.

Improving Safety

Safety is a top priority in any industrial environment. Uninsulated pipes can pose serious hazards, such as burns from hot surfaces or condensation leading to slippery floors. Pipe insulation wrap mitigates these risks by providing a protective layer, reducing surface temperatures, and preventing condensation build-up.

Reducing Environmental Impact

In today’s environmentally conscious world, reducing carbon emissions is essential. By enhancing energy efficiency, pipe insulation wrap contributes to lower greenhouse gas emissions. Industries that adopt efficient insulation practices can significantly decrease their environmental impact, aligning with global sustainability goals.

Minimizing Condensation

Condensation on pipes can lead to a host of problems, including corrosion, mold growth, and water damage. Pipe insulation wrap effectively minimizes condensation by maintaining the surface temperature of the pipes above the dew point. This preventative measure not only protects the pipes but also enhances the overall integrity of the infrastructure.

Extending Equipment Lifespan

The longevity of industrial equipment is directly tied to its maintenance and operating conditions. By reducing temperature fluctuations and protecting against environmental factors, pipe insulation wrap helps extend the lifespan of piping systems and related equipment. This durability translates into long-term savings and reduced downtime for repairs.

Cost-Effective Solution

Investing in pipe insulation wrap is a cost-effective decision for any industry. The initial cost of insulation materials and installation is quickly offset by the savings in energy, maintenance, and equipment replacement. Additionally, many insulation solutions are designed for easy installation, further reducing labor costs.

Customizable and Versatile

Pipe insulation wrap is available in various materials and thicknesses, making it a versatile solution for different applications. Whether dealing with high-temperature industrial pipes or chilled water systems, there is an insulation wrap designed to meet specific needs. This customization ensures optimal performance and energy efficiency for any system.

Conclusion

Pipe insulation wrap is a pivotal component in improving energy efficiency within industrial settings. By reducing heat loss and gain, enhancing system efficiency, and lowering energy consumption, this simple yet effective solution offers numerous benefits. At G & R Insulating, we are committed to providing top-notch insulation services that help industries achieve their energy efficiency goals. Embracing pipe insulation wrap is not only a smart business decision but also a step towards a more sustainable future.

By incorporating pipe insulation wrap into your operations, you can experience significant energy savings, enhanced safety, and a reduced environmental footprint. Trust in the expertise of G & R Insulating to deliver high-quality insulation solutions tailored to your specific needs. Together, we can build a more efficient and sustainable industrial landscape.